PRODUCTS

-

Ventilated membrane

-

Waterproof and breathable valve

-

Plasctic vent assembled by sleeve

-

plasctic vent assembled by hand

-

Plasctic vent assembled by Buckle

-

Plastic vents assembed by twist

-

Plastic vent assembled by rubber

-

Plastic vent assembled by insert

-

Plastic vent assembled by direct insert

-

Metal vent by sleeve

-

Metal vent assmebled by screw-driver

-

Metal vent assmebled by sleeve

-

-

Sound Transparent membrane

-

Special function waterproof and breathable valve

-

Accessory

Gould breathable waterproof membrane to disperse the PTFE resin as raw materials, substrates and the like polytetrafluoroethylene film and polyester stretch laminated puffed after laminating, laminated film before the substrate is polytetrafluoroethylene oil repellency, temperature, flame retardant, UV resistance, hydrophobicity, self-cleaning process. The toughness of the film is treated to improve water resistance and tensile strength.

ePTFE expanded polytetrafluoroethylene membrane is stretched by the expansion made. Polytetrafluoroethylene membrane is stretched after their three dimensional mesh structure is formed, the film surface per square inch, 90 more than one billion micropores. Excellent tensile technique enables the pore diameter is maintained at 0.1 to 3.0 m (0.1 ~ 3.0 × 10-6m) between. More than 10,000 times smaller than water droplets, making ePTFE film having excellent water barrier properties (exceeding IP67 waterproof standard requirements), the smallest water droplets (mist) can not pass through the membrane. At the same time water vapor molecules larger than the pore diameter of more than 700 times. So along with super waterproof (and to prevent oil, dust, bacteria, etc.) properties, but also to allow the gas molecules easily through pores of the membrane, in order to achieve breathability achieve pressure balance function. Thus to eliminate the negative impact of absorbing gas and flatulence compressive stress appears to solve the problem mist.

Processing content:

|

• Hydrophobic treatment

|

• Anti-UV treatment

|

• Ink repellent treatment

|

|

• Oil repellency treatment

|

• Anti-Infrared Processing

|

• Cleaning agent treatment

|

|

• Flame retardant treatment

|

• Mildew treatment

|

• Plastic Sheeting

|

|

|

|

• Refusing blood treatment

|

Feature:

· Excellent self-cleaning

· Various prevents dust outside the machine can maintain a high air flow rate in the case where water impermeable, aerosols and particulates.

· Opening ratio: 85%;

· Pore size distribution can be controlled within 0.01 ~ 5.0μm

· Has a long service life

· Preferably the substrate (polychlorotrifluoroethylene (The ECTFE), and non-woven mesh, polyester, polypropylene)

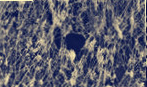

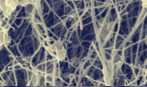

From 2,000 to 10,000 times magnification scanning electron micrograph obvious to see that Arnold uniformity of the film itself, the rigidity of the membrane fiber membrane porosity and other aspects have a distinct advantage.

To give you a more intuitive understanding of our products, please take a look at the microscopic picture.

1

2

3

4

Eliminate the following adverse conditions:

Cracking void formation

Form a block

Uneven porosity

Nodes that disproportionately affect breathability

Cracking less rigid fibers

Generally, we evaluate the quality of the film from the following aspects to:

Membrane pore structure of uniform pore size of the membrane fiber diameter uniformity

Breaking the rigidity of the film fiber membrane fibers

Porosity of the membrane

Elastic recovery of the film

Common diaphragm Figure

General arrangement step

Case picture

Production site

Storage requirements

1、to avoid direct sunlight, near heat sources, avoid dust

2、storage time not exceeding 1 year

Handling Precautions

1、the mounting position of the diaphragm arranged in an upright orientation, in order to avoid dust accumulation

2、applying a clear positioning line position in the installation of the diaphragm is the most limiting step

3、the surface roughness of the installation shall not exceed 0.4 μm Ra.

4、to ensure a clean environment, so as not to interfere with the installation of dust environmental effects

5、the mounting surface to ensure a clean, dry bath

6、avoid spikes touch breathable waterproof membrane components

7、Wear a clean plastic or rubber finger gloves to avoid direct contact with the finger breathable waterproof membrane

8, ready blunt edge not use forceps may damage the waterproof breathable products nipper.

Extracted from the membrane from the profiles

Method 1: roll-off material to make waterproof breathable membrane and release material is separated, isolated and then taken to about 1-2mm seed extract diaphragm

Method 2: the product is put flat on the table, with tweezers and gently stir up the diaphragm, after provoking 1-2mm light tweezers folder directly Gently remove the membrane from the release material

Stickers put the diaphragm

The film accurately placed in the target interval limit

If the secondary mucous membrane sheet should repeal the previous film, the first good cleaning paste interval, re-posted new film

After leaving the good positioning of the diaphragm with your fingers with about 30,000 pa vertical pressure is continuously applied on the diaphragm 5-10 seconds

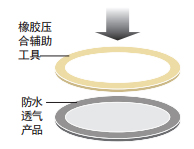

In order to ensure efficient paste, should be used rubber auxiliary nip tool

Rubber aids should coincide with the annular adhesive

About 30 degrees in rubber hardness, thickness of 2 to 5mm

Nip pressure of about 30,000 pa

Auxiliary nip time is approximately 24 hours

Check after installation

1、whether good location

2、from scrap wood materials whether there is attached to the diaphragm, should be removed if attached

3、whether the ash method, foreign bodies, if any should blow

Remove bad patch

If the production or use were found to have bad happens, we need to remove the damaged diaphragm. You can apply 95% alcohol or pharmaceutical white oil clear adhesive on the diaphragm.

| Classification | No. | Material coding | Colour | Size | Specifications |

| Breathable waterproof membrane material | 1 | MPE-0LQ-550015-B22100 | Large amount of ventilation | 55*0 | download spec. |

| Breathable waterproof membrane material | 2 | MPE-0LQ-471515-B22100 | White | 47*15 | download spec. |

| Breathable waterproof membrane material | 3 | MPE-0LQ-140727-B12100 | White | 14*7 | download spec. |

| Breathable waterproof membrane material | 4 | MPE-0LQ-353023-B00500 | 30gWhite | 3.5*3.0 | download spec. |

| Breathable waterproof membrane material | 5 | MPE-0LQ-473210-B00500 | 30gWhite | 4.7*3.15 | download spec. |

| Breathable waterproof membrane material | 6 | MPE-0LQ-292820-B00500 | 30gWhite | 2.9*2.8 | download spec. |

| Breathable waterproof membrane material | 7 | MPE-0LQ-562527-H02680 | Black+white | 5.6*2.5 | download spec. |

| Breathable waterproof membrane material | 8 | MPE-0LQ-763327-H02680 | Black+white | 7.6*3.3 | download spec. |

| Breathable waterproof membrane material | 9 | MPE-0LQ-080527-H02680 | Black+white | 8*5 | download spec. |

| Breathable waterproof membrane material | 10 | MPE-0LQ-090427-H02680 | Black+white | 9*4 | download spec. |

| Breathable waterproof membrane material | 11 | MPE-0LQ-100527-H02680 | Black+white | 10*5 | download spec. |

| Breathable waterproof membrane material | 12 | MPE-0LQ-100627-H02680 | Black+white | 10*6 | download spec. |

| Breathable waterproof membrane material | 13 | MPE-0LQ-120727-H02680 | Black+white | 12*7 | download spec. |

| Breathable waterproof membrane material | 14 | MPE-0LQ-140727-H02680 | Black+white | 14*7 | download spec. |

| Breathable waterproof membrane material | 15 | MPE-0LQ-120827-H02682 | black | 12*8方形 | download spec. |

| Breathable waterproof membrane material | 16 | MPE-0LQ-562527-L02680 | Grey White | 5.6*2.5 | download spec. |

| Breathable waterproof membrane material | 17 | MPE-0LQ-763327-L02680 | Grey White | 7.6*3.3 | download spec. |

| Breathable waterproof membrane material | 18 | MPE-0LQ-080527-L02680 | Grey White | 8*5 | download spec. |

| Breathable waterproof membrane material | 19 | MPE-0LQ-090427-L02680 | Grey White | 9*4 | download spec. |

| Breathable waterproof membrane material | 20 | MPE-0LQ-100527-L02680 | Grey White | 10*5 | download spec. |

| Breathable waterproof membrane material | 21 | MPE-0LQ-100627-L02680 | Grey White | 10*6 | download spec. |

| Breathable waterproof membrane material | 22 | MPE-0LQ-120727-L02680 | Grey White | 12*7 | download spec. |

| Breathable waterproof membrane material | 23 | MPE-0LQ-140727-L02680 | Grey White | 14*7 | download spec. |

| Breathable waterproof membrane material | 24 | MPE-0LQ-149516-L02680 | Grey White | 14.2*9.5 | download spec. |

| Breathable waterproof membrane material | 25 | MPE-0LQ-211827-L02680 | Grey White | 21*18 | download spec. |

| Breathable waterproof membrane material | 26 | MPE-0LQ-312975-H02880 | black+White | 31*26 | download spec. |

| Waterproof breathable film membrane | 27 | MCE-0CK-080310-B00700 | White | - | download spec. |

| Waterproof breathable film membrane | 28 | MCE-0CK-100316-B23700 | White | - | download spec. |

| Waterproof breathable film membrane | 29 | MCE-0CK-100318-B25700 | White | - | download spec. |

| Waterproof breathable film membrane | 30 | MCE-0ML-080310-B00701 | White | - | download spec. |

| Waterproof breathable film membrane | 31 | MCT-0LC-135302-H00800 | blackTPU | - | download spec. |

| Waterproof breathable film membrane | 32 | MCE-0ZT-000010-B00500 | 20gGrey White | - | download spec. |

| Waterproof breathable film membrane | 33 | MCE-0SR-050310-B00500 | 30gGrey White | - | download spec. |

| Waterproof breathable film membrane | 34 | MCE-0BG-135302-H02980 | Pure film | - | download spec. |

| Waterproof breathable film membrane | 35 | MCE-0BG-135310-L02680 | Grey White | - | download spec. |

| Waterproof breathable film membrane | 36 | MCE-0BG-135310-H02680 | black | - | download spec. |

| Waterproof breathable film membrane | 37 | MCE-0BG-135310-H02880 | Black and white film | - | download spec. |

| Waterproof breathable film membrane | 38 | MCE-0BG-135310-Y02680 | Yellow film | - | download spec. |

| Waterproof breathable film membrane | 39 | MCE-0BG-135310-H02680 | black | - | download spec. |

| Waterproof breathable film membrane | 40 | MPE-0LQ-550015-B22100 | Grey White | - | download spec. |

HUIZHOU LEADER ELECTRONIC SCIENCE&TECHNOLOGY CO., LTD.

Service Hotline:400-080-1865

TEL:0752-2601855

FAX:0752-2601865

E-mail:sales@hzlede.com

Address:No. 180 Shenwu Group, Fourth Ring South Road, Henan Bank, Huicheng District, Huizhou

Copyright © ALL RIGHTS RESERVED HUIZHOU LEADER ELECTRONIC SCIENCE&TECHNOLOGY CO., LTD. 粤ICP备15115233号 www.hzlede.com www.300.cn